PRODUCTION

The production process of our bags consists of various stages, from the discarded material being converted into raw material to its transformation into a functional object ready to fulfil its new purpose.

All the production is done locally at our Barcelona workshops, in an ethically-minded collaboration with local providers.

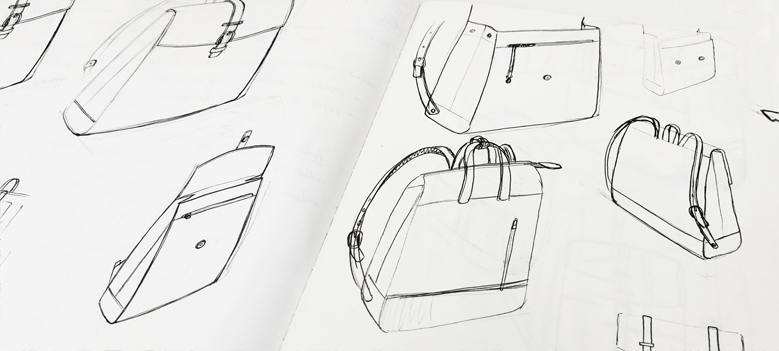

DESIGN

The aim of our design is to create products with maximum functionality, while getting the best performance out of our materials. We analyse their qualities and develop our own prototypes. The idea is to make bags that can accompany you wherever your daily adventures may take you, and to give them the capacity to carry everything you need, adapting to your needs.

SELECTION

Once the materials arrive at our workshop, the first step is selection. When you work with discarded materials, they arrive dirty and wrinkled. We separate the parts that can be salvaged from those that can no longer be used. This process is done manually in our workshop. We select the most interesting parts for conversion into raw materials.

CUTTING PATTERNS

Once the salvageable parts have been selected, we proceed to cut the patterns. We choose the best graphic elements for each part of the bag, combining colours and deciding on the needlework, textures, and prints that we find most interesting.

CLEANING

We clean each one of the pieces by hand. When working with inner tubes, for instance, we clean them beforehand in a 90oC washing machine. This process offers the opportunity to perform quality control tests on all the materials, ensuring that no component is damaged or deteriorated. Sometimes, we will allow for small imperfections because they offer a glimpse into the material’s past life. By this point, we have successfully turned the discarded materials into raw materials for making clothing.

CREATION

Our products are made at professional workshops in Barcelona. We work ethically with local providers because we believe it is the best way of doing business.